The Science of SpaceX Starship’s Thermal Tiles

SpaceX is building a vehicle called Starship that is covered in thermal tiles. These tiles bear a striking resemblance to the tiles used on the space shuttle. The question arises: did SpaceX develop an improved thermal tile recipe, or are they simply copying what NASA was doing 30 years ago?

In order to answer this question, the host of the video conducts an interesting experiment. He has fragments of heat tiles from both the Starship and the shuttle Endeavor, and he puts them under an electron microscope to get a closer look at what’s going on. Additionally, he creates a DIY version using the original recipe from 1978. This allows a better understanding of how the tiles work and how they are manufactured.

The tiles used on both the shuttle and Starship are composed of 99.6% pure amorphous silica fibers, which are chopped into a slurry of short fibers and mixed with a few additional additives like colloidal silica as a binder. The slurry is then placed into a mold, drained of water, and dried out in an oven. Ultimately, the block goes into a furnace, where the temperature is ramped up to 1200° C, causing the fibers to melt and act like a glue, binding adjacent fibers together.

The video also explores the lightweight ceramic tiles that were eventually chosen for the shuttle. These tiles are effective insulators, allowing the exterior to reach 1200° C while the interior remains barely warm to the touch. Despite their insulating properties, the tiles have a fatal flaw, as they are fairly transparent to infrared radiation. To address this, an opaque layer is added on top of the tiles to make the surface opaque and strengthen it.

In conclusion, the video offers an in-depth exploration of the science behind the thermal tiles used on the SpaceX Starship and provides a unique look at the manufacturing process and properties of these remarkable insulating materials.

Watch the video by Breaking Taps

https://www.youtube.com/watch?v=SI7mpjHGiFU

Video Transcript

SpaceX is building a vehicle called Starship and it’s covered in thermal tiles that look suspiciously like the tiles on shuttle has SpaceX developed an improved thermal tile recipe or is it just a copy of what NASA was doing 30 years ago well today we’re going to answer that because I have fragments of

Heat tiles from both Starship and shuttle Endeavor we’ll pop these in the electron microscope and get a closer look at what’s going on but the answer is a little complicated so I made a DIY version using the original recipe from 1978 this will make it easier to

Understand both how they work and how they’re manufactured of course if you have some of these thermal tiles it’s required by law to play around with a propane torch so I did that and I also tried this fun and pretty scary trick with a furnace I’m so scared still

Before shuttle thermal protection was typically accomplished with a blade of shields that literally burn off during re-entry it is manufactured from fiberglass honeycomb filled with silicon elastomer this is what both geminy and Apollo capsules used these worked really well but were heavy and non-reusable the goal of shuttle was a reusable orbitor

So a blade of shielding just really wasn’t an option eventually lightweight ceramic tiles were chosen in June of 1973 Lockheed was chosen to develop and scale up production of these tiles the design was composed of 99.6% pure amorphous silica fibers these are chopped into a slurry of short

Fibers they mixed with a few additional additives colloidal silica is ADD as a binder as well as surfactants and pH buffers the slurry is then dumped into a mold NASA used large plexiglass molds and dump the slurry in with buckets I just use a small 3D printed mold and I

Was aiming for a block about 2 in wide the slurry is then packed in place and the water drained this yields a cube that is mechanically robust enough to handle but it’s still pretty fragile and completely saturated with water it needs to be dried out either in an oven or

Just sitting out overnight once dry the block goes into into a furnace and the temperature is ramped up to 1200° C this temperature is not hot enough to melt or Center the silica fibers purom morphous silica doesn’t really do anything up until about, 1400° but that’s where the colloidal

Silica comes in colloidal silica is it’s basically a suspension of silica nanop particles and because they’re so small they just kind of behave strangely so while the fibers don’t melt at this temperature the nanop particles do they melt and act like a glue binding adjacent fibers together then we pull

The block out of the furnace and nothing there’s nothing there here is the platin and you can see there’s basically a piece of glass uh sitting right here melted onto the base it’s starting to crack from the heat it looks like it just melted but

That I think is it that is the uh the thermal tile so that’s cool it’s not supposed to melt like that uh clearly something went wrong here uh my first guess is that I used Too Much colloidal silicon maybe there was just so much in there that it lowered the melting

Temperature of all the fibers and the whole thing melted I wasn’t really sure but I tried to again in with a lot less of the coloidal silica and I also switched to a furnace where it was a little easier to check progress right we

Are at about 800° C and as you can see it’s already starting to melt or collapse in on itself so I’m going to pop this open there it is you can see it’s not supposed to look like that all right now we are at about 1,000° celius oh

Yeah we’re going to call it that starting to melt so at this point I suspected the fibers were not actually pure silica but some kind of just low melting point glass I tried one final time with just the fibers and no additives just to completely rule out

Any other variables and got the same result you can also notice a pretty distinctive of blue color to the glass and if you look closely the fibers themselves seem pretty bluish pure silica is absolutely clear so I don’t know what it is but it’s definitely not silica I purchased some new fibers from

A different vendor and these look a lot better I reran the whole procedure and there we go a centered block of pure silica fiber this intermediate product is what NASA would call Li 900 there were two variants on the shuttle Li 900 and Li 2200 they are both silic tiles produced

Using the same method the only difference is how dense they are Li 900 had a density of 9 lb per cubic foot and Li 2200 was 22 lb Li 900 was the main density used in most places on the shuttle but the heavier variant was used in a few locations where the extra

Strength was needed like around doors and windows so why did NASA go through all this trouble well this production method generates tiles that are filled with voids as much as 90 to 95% of this tile is just empty air this makes it an amazing insulator which is of course

What you want in a thermal protection system it’s exactly why fiberglass and foam are used as insulation here on Earth the trapped air is what provides the insulation and the more air you trap the better it insulates the thermal tiles are such an effective insulator that the exterior can be 1200° literally

Glowing red and the interior is barely warm to touch this was important because shuttle was mostly built from aluminum and aluminum gets pretty unhappy above 200° C and starts to melt around 600 these tiles are so good you can easily hold a piece in your hand and

Blowtorch it for a few minutes the back side is barely warm despite the surface glowing red and you can see that the black coating on top also radiates the heat away super quickly and the surface cools down incredibly fast there is actually this neat party trick that NASA used to do on tours

Where they would pull a tile out of the furnace and then immediately pick it up this works because the corners are exposed to the air and WRA rapidly cool down but the material is such a good insulator that the interior stays glowing and hot for a really long time

And I don’t know I kind of wanted to try that oh man that’s that’s hot I can feel the heat from here oh no I’m so scared still All right that’s hot that’s still hot that’s still hot my goodness all right so it looks like you have to let it cool down a little bit before you grab it and by time you grab it the uh internal glow kind of goes away which is too bad but it has no

Right to be cooling down that quickly that’s pretty wild at this point however there is a fatal flaw to the tiles despite being a great convective insulator the tiles are fairly transparent to infrared radiation if not addressed radiant heat would cook the shuttle by passing directly through the silica fibers themselves they’re also

Pretty fragile at this stage and you can carve it up like a block of foam just as an aside this is actually the step where NASA would CNC mill them into their final shape so we need to make the tile surface opaque and if possible strengthen it a

Little this is why the tiles on shuttle are black or white there’s an opaque layer that’s been added on top the tiles on the underside of shuttle are black because darker colors radiate heat better and this isn’t just paint because something like paint would immediately burn off it needs to withstand the same

Temperatures as the silica fiber itself instead engineers at am Research Center devised a special type of glass that goes on top this coating is called rcg or reaction cured glass I think I’ll make another video about this glass and how it’s manufactured because it’s pretty complicated and cool in its own

Right but basically you mix up a special batch of Bor silicate glass melt it pour it out boil in acid crush it to powder mix with Boron silicide coat your ceramic tile and glaze it at 1200° C technically it’s a Boro silicate glass but it’s not like the scientific glass

You might use in a chemistry lab the complicated processing steps make it closer to a pure silica than a borosilicate glass and the Boron silicide is added to make it opaque and black all right so this is still cooling down but a couple observations uh one it’s gotten noticeably less dark as it’s

Cooled down uh so this outer glazing you can see the fibers showing through quite a bit more than a couple minutes ago uh two it’s still you know it’s pretty cool to touch on the sides but you can feel quite a bit of heat coming coming off

The black surface so that’s working uh but yeah kind of neat I don’t know why it slumped this much maybe there’s just a hollow I know it’s not very evenly you know it’s not very well packed so it probably just kind of the weight of the glaze settled I don’t know

Pretty cool stuff though I’m disappointed it doesn’t look ow Christ that’s really hot disappointed that the uh the surface isn’t a more even glaze but what are you going to do but after all of that we’re left with a strong glassy layer on top and even though my DIY attempt is I

Mean it’s pretty ugly it holds up to a map torch just fine uh well it worked although I don’t think it works as well as the commercial stuff I notic it definitely cools down a lot slower than the SpaceX stuff it’s almost instant on the SpaceX the red

Spot dissipates and it’s probably just because it’s a very uneven coating like I can see that there’s a lot of silica fiber sticking through here so it’s probably just more or less of this coating on top in different locations but I don’t know I’m pretty happy that

Worked a lot better than I expected it’s interesting to see the black color really comes back when it heats up and you can see the edges here where it’s cooled down the uh clear translucent fibers are starting to show through some more so that’s kind of interesting I’m

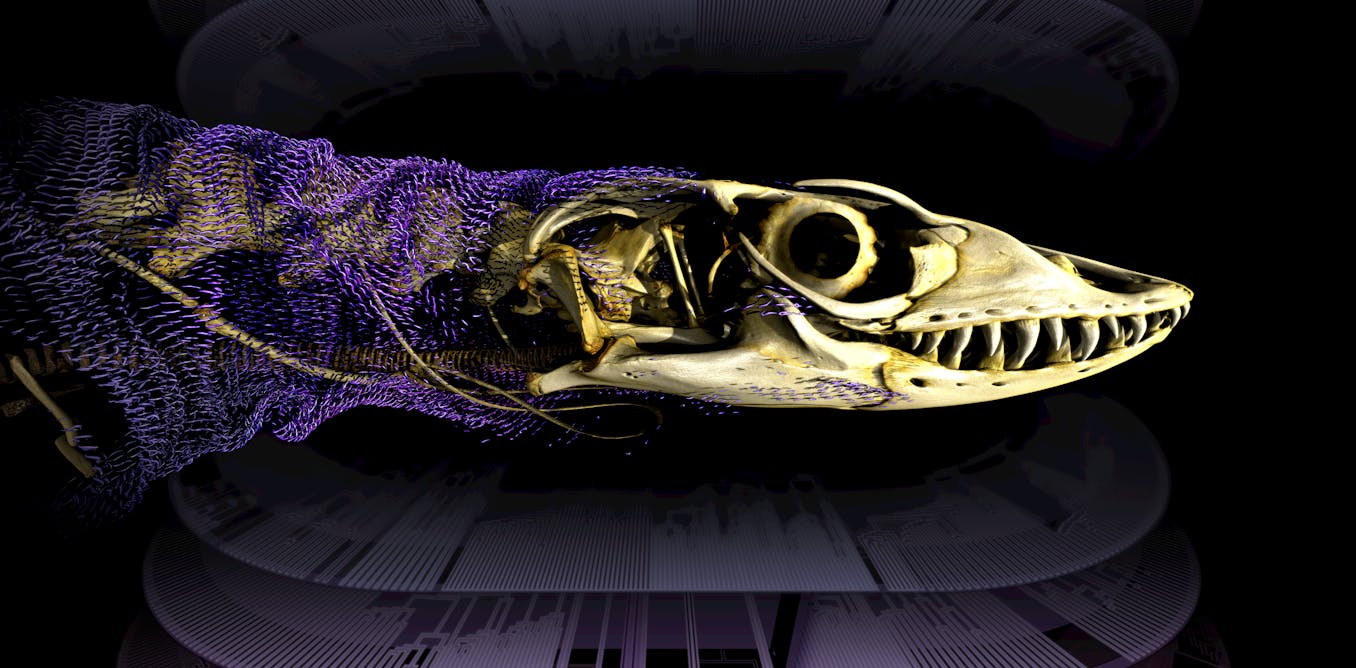

Not sure what’s up with that after being coated these tiles are now called L RSI or hrsi tiles depending on which coating they get now with a crash course of ceramic tile manufacturing under your belt we can take a look at that shuttle fragment this is supposedly a fragment

From shuttle Endeavor removed March 11th 1997 because the tile was was damaged and needed replacing now proving the authenticity of this tile is I mean it’s difficult right bought it on eBay there’s no good way to know that this actually came off shuttle but it’s a pretty Niche material and it’s not

Really something you’re just going to go buy at a hardware store and sell on eBay as a fake tile it could be a fragment of Starship that someone is trying to pass off as a shuttle fragment but I think that’s unlikely cuz they would probably sell better as an actual Starship

Fragment right now and there are some differences between the two that we’ll see in a it so I don’t really know if this is from Endeavor but I feel pretty confident saying it’s at least from the shuttle program there’s not much to see under an optical microscope so let’s

Just jump straight to the electron microscope at the top here we can see the reaction cured glass it’s a solid Consolidated layer without any voids and below it we can see all those silica fibers forming the loose porous structure if we zoom in more we can see

There are actually a few different sizes of fibers in here the smallest are 1 to 5 micrometers in Di diameter and occasionally we’ll see some larger fibers up to 16 microns where the fibers touch there’s a small region where they’re fused together but this fuse region is pretty small which is

Important to help prevent too much heat transfer from one fiber to the next and from looking at these images it becomes clear just how much empty space is in each tile if we turn on the element detector on my microscope we can see silicon and oxygen pretty much

Everywhere as expected there is one Oddity though is that aluminum what’s that doing here I thought this might be like a calibration issue or maybe a weird contamination but after recalibrating and checking some other regions on the sample no I mean that’s that’s actually aluminum on those fibers

We can see that these fibers are predominantly aluminum and oxygen and only a pretty small amount of silicon which is interesting so at this point I was I don’t know pretty confused and maybe thinking that I did actually get scammed but I went back to the literature and

Did some more reading there were a number of improvements made over the years to shuttle including to the thermal tiles so long story short I think this is either an F frci tile or an aetb NASA loves its acronyms so F frci stands for fibrous refractory composite insulation and it’s like a

Stronger tougher form of the tiles we’ve been looking at 22% of the silic fibers are replaced with alumina Boro silicate fibers instead the addition of these fibers reduce the overall weight while improving the mechanical characteristics F frci 12 was introduced in 1981 and replaced hrsi tiles as they were damaged

During missions the other option are aetb tiles which stand for alumina enhanced thermal barrier and these were introduced in 1996 as an improvement to F frci in this formulation some of those alumin Boro silicate fibers are replaced with pure aluminum oxide fibers in both of those cases we’d expect to see some

Of these fibers that are enriched in aluminum either from alumin Boro silicate or from Pure aluminum oxide so I think that’s the mystery solved this is probably just a more modern variant of the hrsi tile which finally brings us back to the SpaceX tiles these fragments are from Starship sn4 which was the

First Starship to experience a uh rapid unscheduled disassembly the first and most notable difference is all of this junk on the sample this crystalline material is basically sea salt and all other stuff that comes from the ocean all these fragments were dumped in the Gulf of Mexico and washed ashore a few

Weeks later the crystals are basically sodium chloride and there’s a fair amount of magnesium and carbon from I don’t know ocean bits so if we want to make a good comparison we need to clean these samples first with deionized water unfortunately all those little air pockets that make it such a good

Insulator also make it float on water and act like it’s hydrophobic I got around this by spraying it with some isopropyl alcohol first IPA has a lower surface tension so it has an easier time infiltrating all the pores and displacing the air and then the water mixes with the IPA

Dilutes it out and you can eventually rinse the whole thing with water after some cleaning you dry it out and we can pop it back in the microscope to see what’s going on so here we can see that the layout is pretty similar to the shuttle tile there’s a thick glassy

Layer on top and a collection of fibers down below there are however some interesting differences the transition from rcg to fiber is much less crisp and it appears slightly porous there’s also a lot more variability in the thickness my shuttle sample was pretty consistently about 200 microns

Thick for the top rcg layer while Starship sample seems to vary from like 80 to 250 microns but having said that it looks like the coating penetrates a lot further into the sample we can see regions of like glassy material several hundred microns below the surface so it

May just be that the Codine penetrates deeper and you get more of a diffuse coating rather than a region of crisp transition like shuttle another difference is the size of the fibers both NASA and SpaceX have small fibers down in that 1 to two Micron range but

While the largest fibers in the NASA fragment were 16 microns some in the SpaceX fragment were as large as 30 microns and in some locations you can see these large fibers have fused together forming a large bundle it’s kind of hard to quantify but I feel like the SpaceX sample just has

More large fibers in general compared to shuttle similar to the shuttle fragment these larger fibers are a mix of aluminum oxygen and silicon so they’re also likely an aluminum oxide or Lumin up borosilicate fiber finally you might have noticed some of these bright spots that are scattered all around heavier

Elements show up as brighter signal when using the back scatter detector on my electron microscope so all these spots represent a heavier metal under the element detector we can see that these spots are actually malum oh my goodness I actually said it right that’s such a

Hard word to say uh right uh it appears present throughout the entire sample both in the glass coating at the surface and throughout the fibrous layer I was concerned this might be some kind of contamination from you know like the ocean that didn’t get cleaned out or

Somewhere in my shop but if we really zoom into the particles we can see that they’re embedded inside the glassy section some particles are sticking out halfway While others are almost entirely covered in glass so I think this is probably an additive in spacex’s coating formula and

Not just a random contamination my best guess is that this is a toughy coating variant this is you guessed it another NASA acronym standing for toughened uniece fibrous insulation it was patented in 1989 but wasn’t really used on shuttle until 1994 and then only in a few locations

Tuffy is basically the same reactive glass material but 20% of it has been replaced with miminum dilde the additive is a high temperature dark material that helps radiate heat just like the Boron Tetra silicide that’s already included but it makes the surface more porous compared to the original recipe it forms

Open pores that prevent cracks from spreading and propagating across the surface which increases the toughness of the material the open pore structure also makes it easier to re-waterproof a tile after they’ve been mounted the tiles have to be periodically re-waterproof after flight and so this small difference can make maintenance a lot

Easier best I can tell toughy was originally used in only a few places like around the main engine despite being tougher it was also a little heavier which restricted its use on shuttle for example the final Atlantis flight in 2011 only had 73 toughy coated tiles compared to thousands of non-

Toughy tiles so where does that leave us with SpaceX my guess is that they’re basically using an aetb fibrous tile with a toughy Coating in effect they’re using one of the most modern variants of the shuttle tile or at least that’s like the heritage of the tile it seems likely

That they’ve tweaked the formula to some degree for example the original viore glass used in the rcg layer is just no longer available it also didn’t look like 20% of the layer was malum so the exact ratios might be a little different here it’s interesting to think about why

SpaceX Engineers chose a toughy related coding by standardizing on a single size a single shape and a single formula that has been proven to be robust SpaceX is probably hoping to avoid many of the thermal tile issues that plagued shuttle even if it does cost a little bit more

Weight three quick editorial notes uh while working on getting b-roll footage for this video I noticed uh you can actually see where tiles have popped off of Starship during the second launch if2 uh so there’s very obviously tiles missing on this black heat shield so clearly there’s still some work to be

Done about how SpaceX is attaching these tiles which is interesting and perhaps not surprising because this was one of the main problems that shuttle faced as well keeping the tiles firmly attached to uh the spacecraft I also have two updates about the thermal tile that I made while working on this project my

Scanning electron microscope actually died kind of in the middle of it uh the turbomolecular pump gave up the ghost so it’s currently out of and I wasn’t able to get any images of my DIY attempt or analyze what the the bad fibers that ended up melting into

Glass um couldn’t analyze what it was actually made out of I mentioned this on social media somewhere and the folks at MVA scientific Consultants reached out and said hey we’ve got sems would you like us to take a few pictures for you uh so not sponsored or anything they

Just were being very generous and offering their services the bad silica fibers look like they’re basically just soda lime glass which tracks with the temperatures I was seeing kind of melting at 800 to 1,000° C is pretty in line with a soda lime so that’s not surprising kind of amusing that they

Were sold as pure silica fibers though I also have some photos of the thermal tile that I made and the results are interesting certainly not what I was expecting all of this like cracked desert surface filling the voids in between the fibers was very unexpected

I’m not fully sure I know what this is I think it’s the colloidal silica binder that like Wicked to the edge of the sample and then melted and formed a glassy layer filling all the pores it’s hard to say if this is everywhere or just on the edges looking at the samples

Under my Optical microscopes I think it’s just on the outer surface that was exposed to the furnace whereas like the interior surface is still Loosey and fibrous as you’d expect but yeah just kind of an interesting artifact and uh I imagine the original Engineers had to

Deal with a lot of problems like this you know it’s probably down to percentages of the binder and how you dry it and process it to avoid this kind of morphology because this would be really bad for a shuttle tile U because it basically increases the surface area more heat

Conduction Less open pore space it would just be a worse thermal tile so yeah just thought that was kind of interesting and would put in a little editorial note here about it if you made it this far into the video I have some good news for you real engineering has

Been working on an excellent three-part series about shuttle but there’s an additional 35 minutes of extra material on nebula this includes the full tour of Atlantis explained by astronaut Bruce Melnick and a 20-minute interview with Bruce himself but on Endeavor on the second flight we actually started

Feeling something to kind of shock the shuttle on the way in and we didn’t know what that was here is a new spaceship wondering what what that is but they’re both really interesting and great companions to part one and two I’m also happy to say that a few more Hands-On

Creators have joined nebula recently Joel from ANA joined a few months back so you can get your fill of questionably safe garage rockets and engines and Justin from thorum just joined the nebula family too including 30 minutes of extra mummy Shenanigans to complement the main mummy Masterpiece that he

Recently released seriously if you haven’t watched this yet you’re missing out you should go check it out out I’ve been part of nebula for a while now and all the folks that have signed up using my code really help keep this channel running projects can get kind of expensive sometimes but signups and

Watch time on nebula provide funds that help me purchase things like fragments of thermal tiles and sketchy silica fibers I’d thank all my nebula viewers but they’ll never see this section because videos on nebula are entirely adree you also have access to nebula Originals which are highquality nebula

Only feature Productions as well as podcasts and cl classes you’ll also help support other channels like real engineering intea and thought Emporium each time you watch videos on nebula it’s honestly a great value filled with wonderful creators and I’m really excited to see the group of DIY science

And garage Engineers continue to grow over time on nebula you can sign up at go. nebula.jpg I think that’s all I got for you thanks for watching and I’ll see you next time

Video “The Science of SpaceX Starship’s Thermal Tiles” was uploaded on 02/13/2024 to Youtube Channel Breaking Taps

The post “A Scientific Exploration – Video – GretAi News” by GretAi was published on 02/17/2024 by news.gretai.com