At TSMC’s North American Technology Symposium on Wednesday, the company detailed both its semiconductor technology and chip-packaging technology road maps. While the former is key to keeping the traditional part of Moore’s Law going, the latter could accelerate a trend toward processors made from more and more silicon, leading quickly to systems the size of a full silicon wafer. Such a system, Tesla’s next generation Dojo training tile is already in production, TSMC says. And in 2027 the foundry plans to offer technology for more complex wafer-scale systems than Tesla’s that could deliver 40 times as much computing power as today’s systems.

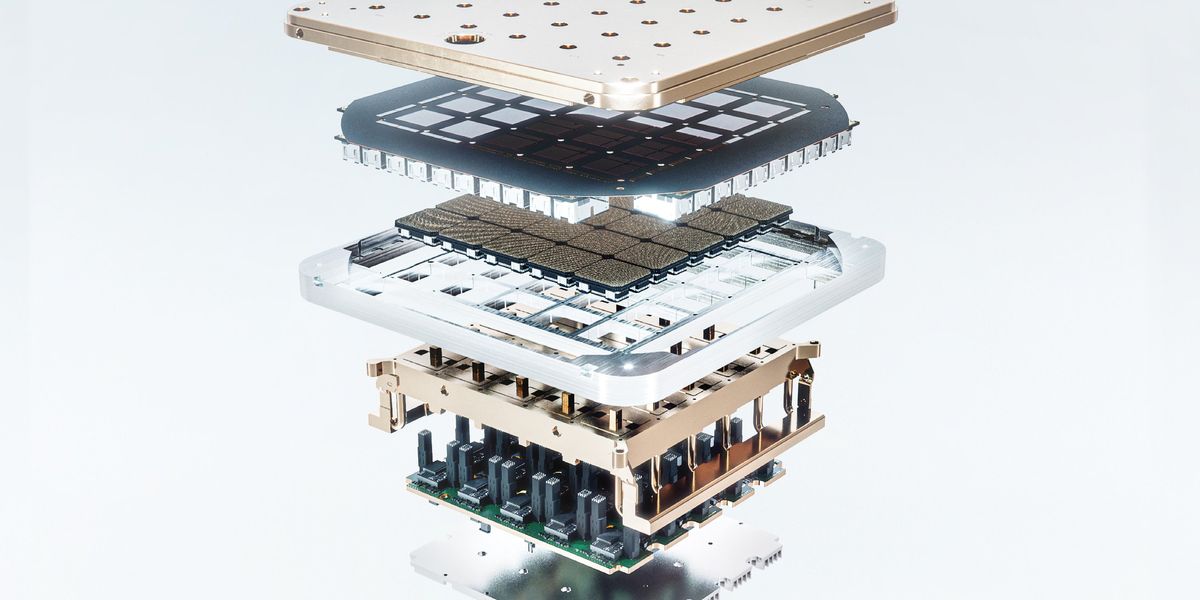

For decades chipmakers increased the density of logic on processors largely by scaling down the area that transistors take up and the size of interconnects. But that scheme has been running out of steam for a while now. Instead, the industry is turning to advanced packaging technology that allows a single processor to be made from a larger amount of silicon. The size of a single chip is hemmed in by the largest pattern that lithography equipment can make. Called the reticle limit, that’s currently about 800 square millimeters. So if you want more silicon in your GPU you need to make it from two or more dies. The key is connecting those dies so that signals can go from one to the other as quickly and with as little energy as if they were all one big piece of silicon.

TSMC already makes a wafer-size AI accelerator for Cerebras, but that arrangement appears to be unique and is different from what TSMC is now offering with what it calls System-on-Wafer.

In 2027, you will get a full-wafer integration that delivers 40 times as much compute power, more than 40 reticles’ worth of silicon, and room for more than 60 high-bandwidth memory chips, TSMC predicts

For Cerebras, TSMC makes a wafer full of identical arrays of AI cores that are smaller than the reticle limit. It connects these arrays across the “scribe lines,” the areas between dies that are usually left blank, so the wafer can be diced up into chips. No chipmaking process is perfect, so there are always flawed parts on every wafer. But Cerebras designed in enough redundancy that it doesn’t matter to the finished computer.

However, with its first round of System-on-Wafer, TSMC is offering a different solution to the problems of both reticle limit and yield. It starts with already tested logic dies to minimize defects. (Tesla’s Dojo contains a 5-by-5 grid of pretested processors.) These are placed on a carrier wafer, and the blank spots between the dies are filled in. Then a layer of high-density interconnects is constructed to connect the logic using TSMC’s integrated fan-out technology. The aim is to make data bandwidth among the dies so high that they effectively act like a single large chip.

By 2027, TSMC plans to offer wafer-scale integration based on its more advanced packaging technology, chip-on-wafer-on-substrate (CoWoS). In that…

Read full article: Expect a Wave of Wafer-Scale Computers

The post “Expect a Wave of Wafer-Scale Computers” by Samuel K. Moore was published on 04/30/2024 by spectrum.ieee.org