A new ultra-energy-efficient tiny laser on a chip could enable powerful medical sensors to fit within a phone, new research finds.

The new device is a kind of frequency comb—a specialized laser that generates multiple wavelengths of light, each at a regular frequency interval. On a spectrogram it would look a bit like the teeth of a comb. In the roughly quarter century since they were first developed, these “rulers for light” have revolutionized many kinds of high-precision measurement, from timekeeping to molecular detection. In addition, each line of a comb can be isolated and have properties such as its amplitude modulated to carry data over fiber optics.

However, frequency combs typically require bulky, costly, and power-hungry equipment. This has largely limited their use to laboratory settings.

Now, scientists at Stanford University employed two different methods that previous work explored to create microchip-scale frequency combs. One strategy, called optical parametric oscillation, involves bouncing beams of laser light within a crystal, resulting in light organizing itself into pulses of coherent, stable waves. The other approach, known as phase modulation, sends laser light into a cavity and then applies radio-frequency signals to control the phase of the light, generating frequency repetitions for use in combs. However, both of these strategies come with drawbacks, such as energy inefficiency and a limited ability to adjust optical parameters.

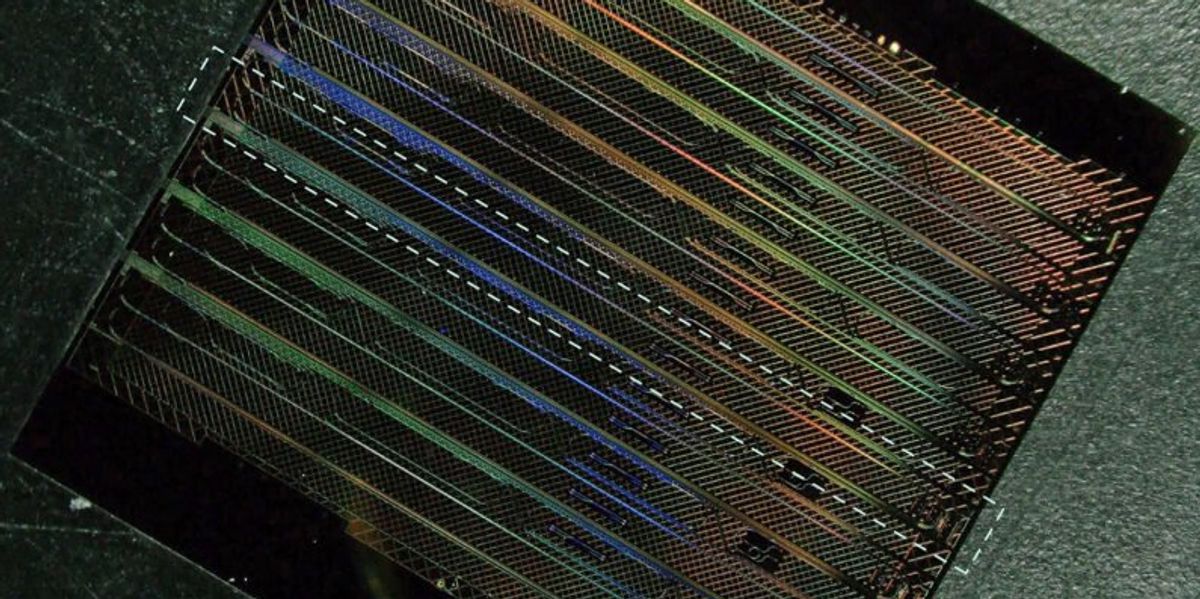

The resulting “microcomb” is just 1 by 10 millimeters in size

To overcome these challenges, the scientists experimented with a material called thin-film lithium niobate, which has a number of advantages compared to silicon, the industry standard material. Two of these properties include how a broad range of light wavelengths can pass through it, and how it can allow light beams of different wavelengths to interact with each other to generate new wavelengths.

The new material accommodated both optical parametric amplification and phase modulation within a single cavity. The resulting “microcomb” is just 1 by 10 millimeters in size. Such a compact size suggests it could find use in personal devices the size of a phone or smaller, the researchers say. It could also be easily made at conventional microchip fabs, they add.

“The most surprising aspect of this comb was how well it performed, in terms of bandwidth and spectrum and efficiency,” says Amir Safavi-Naeini, an associate professor of applied physics at Stanford University.

Instead of generating pulses of light as the researchers expected, the new microcomb unexpectedly produced a continuous output. Other combs waste power in between pulses. As a result, the scientists could reduce the input power the device required by roughly an order of magnitude.

A High Efficiency, High Performance Frequency Comb

The new device’s efficiency at converting light pumped into the cavity into a comb exceeded 93 percent. It could generate 200 comb…

Read full article: Frequency Combs: A Laser Chip for a New Generation of Sensors

The post “Frequency Combs: A Laser Chip for a New Generation of Sensors” by Charles Q. Choi was published on 03/12/2024 by spectrum.ieee.org