High temperature reactors for industrial processes like steelmaking and hydrogen gas production must operate at hundreds to thousands of degrees Celsius. Traditionally, fossil fuels are used to heat a transfer liquid that is then pumped into the reactor to create these scorching temperature. Researchers at Stanford have developed a new approach using electricity, which could come from green sources, to do the job much more efficiently.

The process, described last month in Joule, is based on high-frequency magnetic induction, and it’s essentially the same process used in modern induction stovetops for the home. When you pass an alternating magnetic field through an electrically conductive material such as steel, the magnetic field induces eddies of current in the material, and these currents heat the material. Unlike using an external heat source such as a flame, this inductive heat is generated evenly throughout the material at the same time.

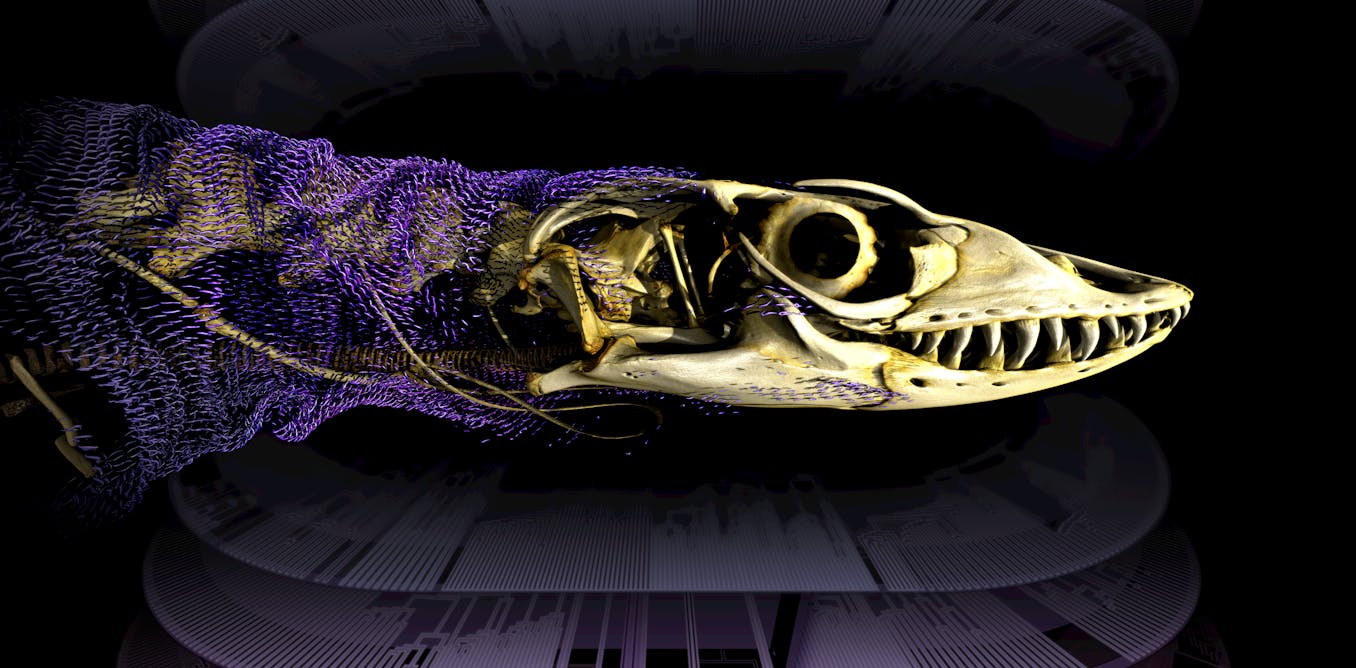

Instead of using steel as the resistive material, the Stanford scientists created a reactor using an electrically conductive ceramic metamaterial. (Metamaterials are structured composite materials that exhibit properties not found individually in its constituents.) A power source generating an alternating magnetic field at megahertz frequencies induces even heating througout the metamaterial, producing the high temperatures required by industrial-level chemical processes.

The result is a self-contained, internally heated thermochemical reactor that can be encased in insulation instead of conductive metal. This design eliminates the combined inefficiencies of burning fossil fuels, heating a transfer fluid, and then transporting that fluid to the reactor chamber. This increased efficiency alone can reduce the carbon footprint for the process.

Metamaterials for electricity conduction and chemistry

The researchers were able to create a ceramic metamaterial with low electrical conductivity and a lattice structure that is mostly empty. Like a sponge, this greatly increases the surface area of the material which in turn creates additional benefits. First, it serves to reduce the conductivity of the ceramic even further, which helps it heat faster and more efficiently. The voids in the lattice also greatly increase the surface area within the reactor, so it comes in contact with the reagents more thoroughly and transfers the heat more efficiently. And these voids can also contain catalysts that will speed the reactions.

“[These] concepts really require a new breed of engineer, the electrical-chemical engineer, who understands as much about chemical industrial processes as power electronics.”

To demonstrate the practicality of this new design, the research team created a lab-scale reactor to convert captured carbon dioxide and hydrogen into syngas, a chemical mixture that can be used to create sustainable fuels or other useful materials. They also were able to demonstrate that the reactor operated at 85 percent…

Read full article: Metamaterials Make High Temperature Industrial Chemicals Greener

The post “Metamaterials Make High Temperature Industrial Chemicals Greener” by Alfred Poor was published on 09/23/2024 by spectrum.ieee.org

Leave a Reply